Motivation

I had to upgrade the Lego table I made when my kids were much smaller. It needed to be higher and include storage options. Since I’m short on time, I used several existing automation tools to both teach my daughter the power of programming and explore our decision space. The goals were to stay low-cost and make the table as functional as possible in the shortest time possible.

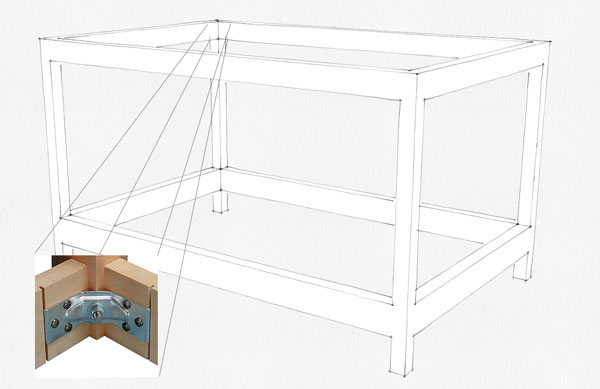

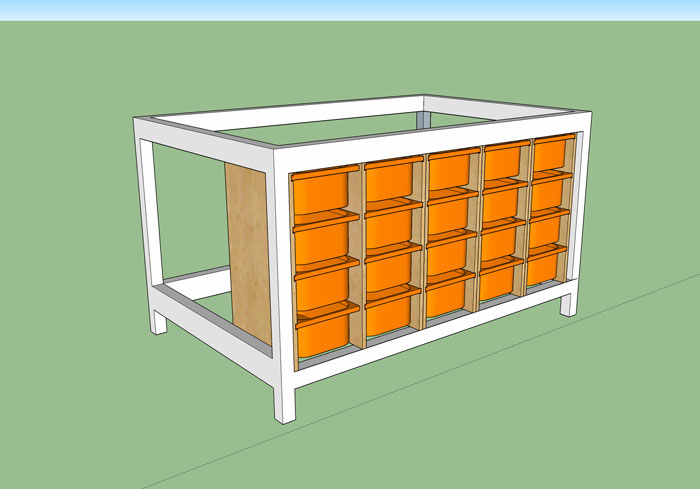

Lauren and I had fun drawing the new design in SketchUp. I then went to the Arlington TechShop and build the frame easily enough from a set of 2x4s. In order to be low-cost and quick, we decided to use the IKEA TROFAST storage bins. We were inspired from lots of designs online such as this one:

However, the table I designed was much bigger and build with simple right angles and a nice dado angle bracket to hold the legs on.

The hard part was figuring out the right arrangement to place the bins underneath the table. Since my background is in optimization I was thinking about setting up two-dimensional knapsack problem but decided to do brute-force enumeration since the state-space was really small. I built two scripts: one in Python to numerate the state space and sort the results and one in JavaScript, or Extendscript, to automate Adobe Illustrator to give me a good way to visually considered the options. (Extendscript just looks like an old, ES3, version of Javascript to me.)

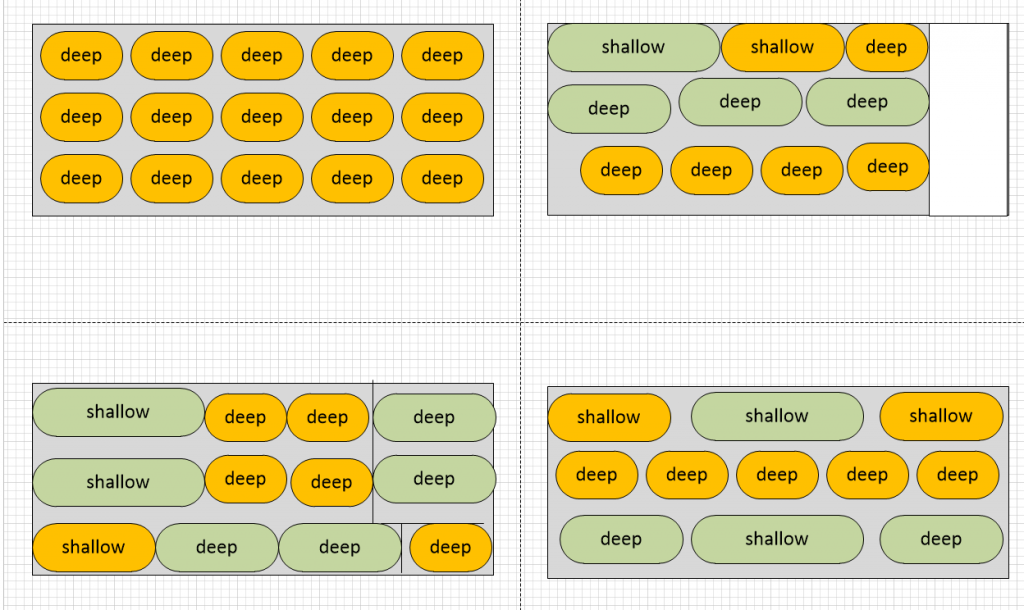

So what are the options?

There are two TROFAST bins I found online. One costs \$3 and the other \$2. Sweet. You can see their dimensions below.

They both are the same height, so we just need to determine how to make the row work. We could arrange each TROFAST bin on the short or long dimension so we have 4 different options for the two bins:

| Small Side | Long Side | |

|---|---|---|

| Orange | 20 | 30 |

| Green | 30 | 42 |

First, Lauren made a set of scale drawings of the designs she liked, which allowed us to think about options. Her top left drawing, ended up being our final design.

I liked her designs, but it got me thinking what would all feasible designs look like and we decided to tackle this since she is learning JavaScript.

Automation

If we ignore the depth and height, we then have only three options $[20,30,42]$ with the null option of $0$ length. With these lengths we can find the maximum number of bins if the max length is $112.4 \text{cm}$. Projects like this always have me wondering how to best combine automation with intuition. I’m skeptical of technology and aware that it can be a distraction and inhibit intuition. It would have been fun to cut out the options at scale or just to make sketches and we ended up doing those as well. Because I’m a recreational programmer, it was fairly straightforward to enumerate and explore feasible options and fun to show my daughter some programming concepts.

$$ \left\lfloor

\frac{112.4}{20}

\right\rfloor = 5 $$

So there are $4^5$ or $1,024$ total options from a Cartesian product. A brute force enumeration would be $O(n^3)$, but fortunately we have $\text{itertools.product}$ in python, so we can get all our possible options easily in one command:

itertools.product([0,20,30,42], repeat=5)

and we can restrict results to feasible combinations and even solutions that don’t waste more than 15 cm. To glue Python and Illustrator together, I use JSON to store the data which I can then open in Illustrator Extendscript and print out the feasible results.

Later, I added some colors for clarity and picked the two options I liked:

These both minimized the style of bins, were symmetric and used the space well. I took these designs forward into the final design. Now to build it.

Real Math

But, wait — wrote enumeration? Sorry, yes I didn’t have much time when we did this, but there are much better ways to do this. Here are two approaches:

Generating Functions

If your options are 20, 30, and 40, then what you do is compute the coefficients of the infinite series

$$(1 + x^{20} + x^{40} + x^{60} + …)(1 + x^{30} + x^{60} + x^{90} + …)(1 + x^{40} + x^{80} + x^{120} + …)$$

I always find it amazing that polynomials happen to have the right structure for the kind of enumeration we want to do: the powers of x keep track of our length requirement, and the coefficients count the number of ways to get a given length. When we multiply out the product above we get

$$1 + x^{20} + x^{30} + 2 x^{40} + x^{50} + 3 x^{60} + 2 x^{70} + 4 x^{80} + 3 x^{90} + 5 x^{100} + …$$

This polynomial lays out the answers we want “on a clothesline”. E.g., the last term tells us there are 5 configurations with length exactly 100. If we add up the coefficients above (or just plug in “x = 1”) we have 23 configurations with length less than 110.

If you also want to know what the configurations are, then you can put in labels: say $v$, $t$, and $f$ for twenty, thirty, and forty, respectively. A compact way to write $1 + x^20 + x^40 + x^60 + … is 1/(1 – x^20)$. The labelled version is $1/(1 – v x^20)$. Okay, so now we compute

$$1/((1 – v x^{20})(1 – t x^{30})(1 – f x^{40}))$$

truncating after the $x^{100}$ term. In Mathematica the command to do this is

Normal@Series[1/((1 - v x^20) (1 - t x^30) (1 - f x^40)), {x, 0, 100}]

with the result

$$1 + v x^{20} + t x^{30} + (f + v^2) x^{40} + t v x^{50} + (t^2 + f v + v^3) x^{60} + (f t + t v^2) x^{70} + (f^2 + t^2 v + f v^2 + v^4) x^{80} + (t^3 + f t v + t v^3) x^{90} + (f t^2 + f^2 v + t^2 v^2 + f v^3 + v^5) x^{100}$$

Not pretty, but when we look at the coefficient of $x^{100}$, for example, we see that the 5 configurations are ftt, ffv, ttvv, fvvv, and vvvvv.

Time to build it

Now it is time to figure out how to build this. I figured out I had to use $1/2$ inch plywood. Since I do woodworking in metric, this is a dimension of 0.472 in or 1.19888 cm.

$31.95 / each Sande Plywood (Common: 1/2 in. x 4 ft. x 8 ft.; Actual: 0.472 in. x 48 in. x 96 in.)

or at this link

So the dimensions of this are the side thickness $s$ and interior thickness $i$ with shelf thickness $k$. Each shelf is $k = 20-0.5 \times 2 \text{cm} = 19 \text{cm}$ wide. All together, we know:

$$w = 2\,s+5\,k+4\,i $$

and the board thickness is $t$ where $t < [s, i]$.

which gives us:

| st | width |

|---|---|

| s | 1.20 |

| i | 3.75 |

| k | 19.00 |

| w | 112.40 |

Code

The code I used is below:

Leave a Reply