Gate Automation

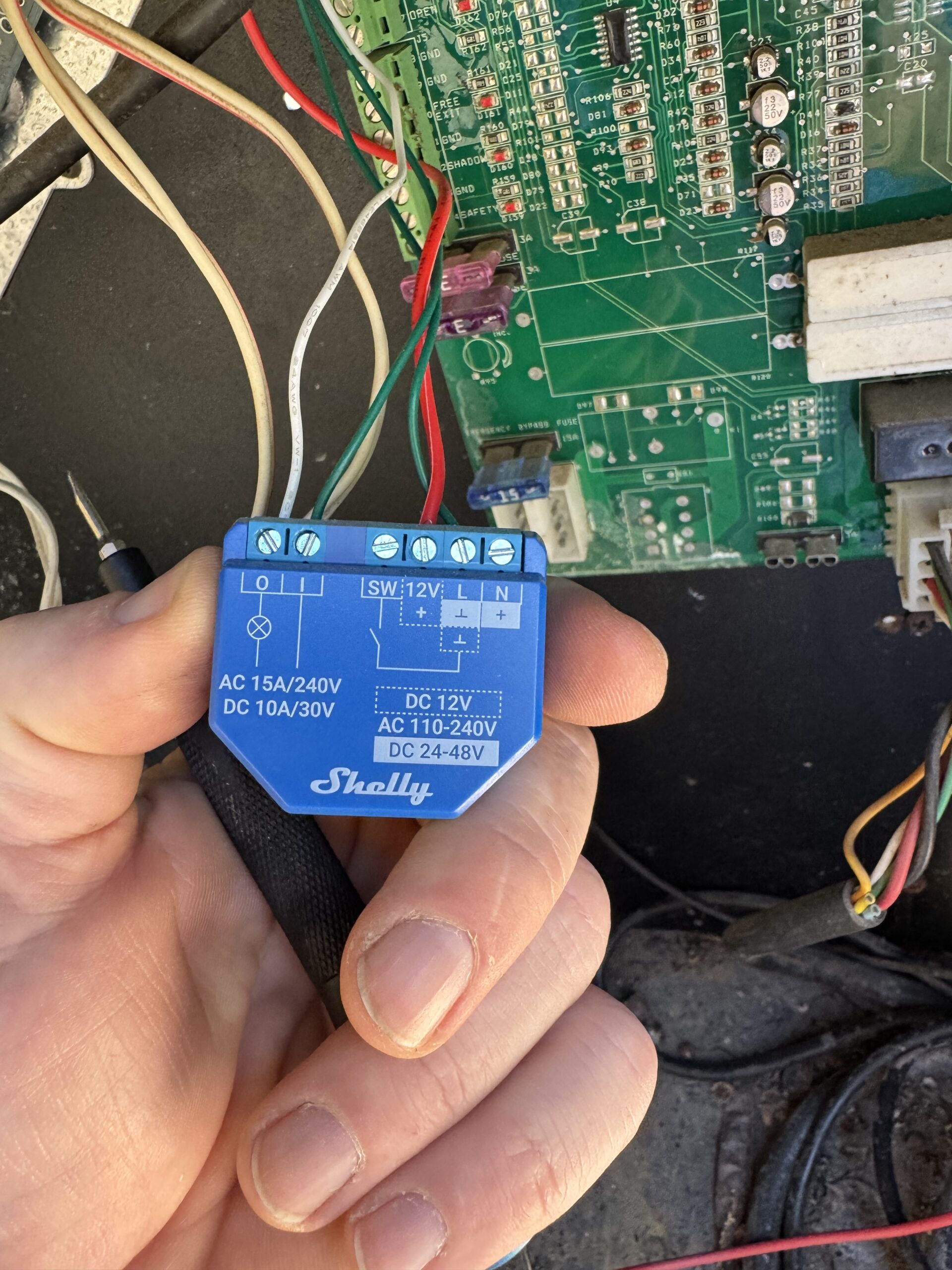

Our gate is the most important motor in our home. It’s critical for security, and if it’s open, the dog escapes. As all our kids cars go in and out, it’s always the gate opening and closing. It matters. The problem is that we have to open it and we don’t always have our phones … Read more